Description

Product Description

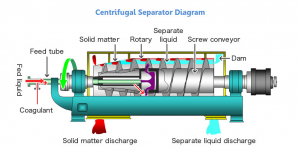

The distiller’s grain separator is characterized in that it includes a feeding mechanism, a drum mechanism is arranged below the feeding mechanism, a pneumatic mechanism and a discharging mechanism are arranged on the drum mechanism, and a power support mechanism is also arranged on the outside of the drum mechanism .

Grain, rice husks and koji are mixed together, and the residue left after the cellar microbial fermentation and distillation to obtain the wine is called distillers grains. The distiller’s grains are rich in protein, fat, starch and amino acids. It has always been a good feed for farmers and herdsmen to feed pigs and fish.

In recent years, major feed manufacturers have used dried and crushed distiller’s grains as raw materials to produce compound feed and full-price feed. However, due to the large amount of rice husk in the distiller’s grains, the crude fiber content in the distiller’s grains is too high, as high as 24%, and the relative protein content is relatively high.

Low, seriously affecting the palatability and feeding effect of distiller’s grains, the price is getting lower and lower, and the number of users is decreasing. The distiller’s grains can’t be disposed of, and if they accumulate in the winery, they will become moldy, and even grow maggots, which will pollute the environment and waste resources.

Full process:

- Drying, using a chain grate hot blast stove to heat the drum dryer, drying the distiller’s grains to a moisture content of less than 10%, and then separating the solid and gas through a cyclone separator;

- Conveying, convey the dried distiller’s grains to the feed inlet of the distiller’s grain separator through a belt or screw conveyor. During the conveying process, iron, stones and mud in the distiller’s grains need to be removed;

- Kneading, kneading the conveyed distiller’s grains through the rollers in the distiller’s grain separator, and forcibly separating the husk and grain residue;

- Impact: The high-pressure air blown from the wind pipe in the distiller’s lees separator blows the kneaded distiller’s grains against the screen, causing the distiller’s grains to collide with the screen or collide with each other, so that the lees has not been completely separated from the chaff in step C. The incoming grain residue was completely separated from the impact;

- Screening: Separate the bran shell, grain residue and ash in the distiller’s grains through the coarse screen and the fine screen in the distiller’s grain separator, the bran shell stays in the coarse screen, and the grain residue stays in the fine screen , The ash stays on the wall of the steel cylinder;

- Diversion, discharge the bran shell, grain residue and ash from the bran shell, grain residue and ash port in the distiller’s grain separator respectively

Main Specification

| Model | Capacity (L/H) | Inlet pressure | Outlet pressure | Motor power( Kw) | Weight (kg) | Dimension |

| SYN360 | 2000-5000 | 0.05 | 0.1-0.35 | 7.5 | 1200 | 1500*1150*1500 |

| SYN470 | 5000-10000 | 0.05 | 0.1-0.4 | 15 | 1600 | 1800*1200*1800 |

| SYN550 | 10000-20000 | 0.05 | 0.1-04 | 22 | 2300 | 1850*1550*2050 |

| SYN616 | 25000-35000 | 0.1 | 0.3 | 37 | 3300 | 2050*1700*2300 |

* Solid-liquid separation

* Liquid-liquid separation

* Liquid-liquid-solid separation

Structure

Application

Dairy separator: used for milk skimming or milk clarification (removal of solid impurities). The small separator is driven by hand and is used for manual slagging, which is suitable for farmers and herdsmen in pastoral areas; the large separator is used for industrial production and is driven by electricity. The slagging method is manual slagging or ring valve slagging.

Mineral oil separator: It is used to remove water and mechanical impurities from mineral oil such as fuel oil, diesel oil, lubricating oil and transformer oil, and can also separate similar emulsions.

Vegetable oil separator: used for the processing and refining of vegetable oil.

Animal oil separator: used for refining animal fats in meat processing, or used for concentration and separation of fish oil in aquatic processing.

Yeast separator: used to concentrate yeast and discharge slag from nozzles.

Starch Separator: Used for removing protein from starch and concentrating starch, and discharging slag from nozzle.

Lanolin Separator: It is used in wool spinning industry to extract wool grease from wool washing water and discharge slag from nozzles.

Pharmaceutical disc separator: used in the extraction of antibiotics, vitamins, etc. in the pharmaceutical industry, and also suitable for the separation of liquid-liquid-solid three-phase mixtures in pharmaceutical and chemical production.

Beer separator: used for clarification of beer, wort and other beverages.

Latex separator: used to concentrate and remove impurities in rubber latex.

Paint separator: used to separate impurities in paint and improve the quality of paint.

Packing,Storage,Handling and Transportation

Certificate

FAQ

Product Warranty:

The guarantee period is 12 months from the date of putting the equipment into operation, but not more than 15 months from the date of delivery.

Free service within warranty:

During a warranty period of exploitation the Seller undertakes to execute warranty service of the equipment, troubleshooting and replacement of out of service spares, except for breakings, bound with incorrect exploitation of the equipment by the Buyer.

Set-up and adjusting of the equipment

After receiving the delivered Goods, the Buyer is obliged to prepare, obtained equipment and applicable lodgment for its installation. Then in written form to inform the Seller on readiness of the equipment for chief- equipment installation, start-up and adjusting.

If necessary,The Seller should send enough technical specialists to help execute the chief – equipment installation, start-up and adjusting equipment on the sight of the Buyer.

Export Packing

The Goods are to be shipped in export packing suitable for the type of goods to be delivered. Packing is to protect the Goods against any damage or corrosion when the Goods are transported by sea or by railway and to provide for possible transshipment of the goods on the way to the place of destination and for a long storage of the goods.

Contact

Vivian Deng

Celll/Whastapp:+86 18040529186

Email:[email protected]

Reviews

There are no reviews yet.