Description

Product Description

Starch centrifuges are mainly used for the production of starch refining raw materials such as corn, cassava, potatoes, wheat, etc. It is mainly used for pre-concentration of puree, separation of gluten and starch, gluten concentration, and washing and clarification of subsequent processes. An extremely important role. It can also be used to pre-concentrate, separate, concentrate and clarify two different materials in the medicine, chemical, and food industries that are compatible with the functions of this machine.

- The starch centrifuge adopts the upper suspension drive mode, the bearing and the main shaft only bear the weight of the rotor, not the huge radial thrust, so the life of the bearing and the main shaft is greatly improved;

- The diameter of the drum and the disc is large, the processing capacity is large, the material stays in the drum for a long time, and the separation effect is good;

- The nozzle with cam lock is adopted, and the nozzle tail adopts a patented special-shaped groove, which makes replacement more convenient. The nozzle will not be damaged due to disassembly, and the large aperture is not easy to block, which ensures the continuous operation of the separator;

- The use of high-precision bearings and an automatic lubrication system ensure the accuracy and reliability of lubrication. Among them, the MH36 centrifuge adopts a water cooling system for the first time in China, which can effectively control the temperature rise of the bearing and avoid high temperature on the lubricating oil. The influence of performance effectively ensures the lubrication conditions of the bearing, improves the running stability, and prolongs the service life of the bearing;

- The high-quality transmission belt is selected to ensure the service life and reliability of work;

- In order to improve safety, the starch centrifuge monitors the vibration of the rotor, the verticality of the main shaft and the speed of the main shaft in real time, and records all changes, and alarms when necessary, making it easier for the operator to grasp and understand the equipment Status, which can effectively ensure the safety of man and machine;

- It has an advanced lubrication system, which can effectively control the lubrication state and temperature rise of the bearing, thereby ensuring the continuous and stable operation of the equipment; the separator has complete safety protection facilities;

8) An automatic control system can be configured, which can monitor the operating status of the equipment in real time, and record various operating parameters, which is convenient for the operator to analyze and research to improve the operation level;

- Because the rotor adopts higher precision dynamic balance requirements, it ensures more stable operation;

- Each bearing point is equipped with a temperature sensor, so that the operating status of the bearing can be known at any time;

- Using hydraulic cylinder column support method, it is more convenient to clean the disc.

Main Specification

| Model | Capacity (L/H) | Inlet pressure | Outlet pressure | Motor power( Kw) | Weight (kg) | Dimension |

| SYN360 | 2000-5000 | 0.05 | 0.1-0.35 | 7.5 | 1200 | 1500*1150*1500 |

| SYN470 | 5000-10000 | 0.05 | 0.1-0.4 | 15 | 1600 | 1800*1200*1800 |

| SYN550 | 10000-20000 | 0.05 | 0.1-04 | 22 | 2300 | 1850*1550*2050 |

| SYN616 | 25000-35000 | 0.1 | 0.3 | 37 | 3300 | 2050*1700*2300 |

* Solid-liquid separation

* Liquid-liquid separation

* Liquid-liquid-solid separation

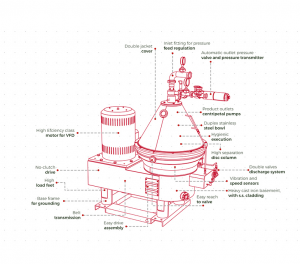

Structure

Application

Dairy separator: used for milk skimming or milk clarification (removal of solid impurities). The small separator is driven by hand and is used for manual slagging, which is suitable for farmers and herdsmen in pastoral areas; the large separator is used for industrial production and is driven by electricity. The slagging method is manual slagging or ring valve slagging.

Mineral oil separator: It is used to remove water and mechanical impurities from mineral oil such as fuel oil, diesel oil, lubricating oil and transformer oil, and can also separate similar emulsions.

Vegetable oil separator: used for the processing and refining of vegetable oil.

Animal oil separator: used for refining animal fats in meat processing, or used for concentration and separation of fish oil in aquatic processing.

Yeast separator: used to concentrate yeast and discharge slag from nozzles.

Packing,Storage,Handling and Transportation

Certificate

FAQ

Product Warranty:

The guarantee period is 12 months from the date of putting the equipment into operation, but not more than 15 months from the date of delivery.

Free service within warranty:

During a warranty period of exploitation the Seller undertakes to execute warranty service of the equipment, troubleshooting and replacement of out of service spares, except for breakings, bound with incorrect exploitation of the equipment by the Buyer.

Set-up and adjusting of the equipment

After receiving the delivered Goods, the Buyer is obliged to prepare, obtained equipment and applicable lodgment for its installation. Then in written form to inform the Seller on readiness of the equipment for chief- equipment installation, start-up and adjusting.

If necessary,The Seller should send enough technical specialists to help execute the chief – equipment installation, start-up and adjusting equipment on the sight of the Buyer.

Export Packing

The Goods are to be shipped in export packing suitable for the type of goods to be delivered. Packing is to protect the Goods against any damage or corrosion when the Goods are transported by sea or by railway and to provide for possible transshipment of the goods on the way to the place of destination and for a long storage of the goods.

Contact

Vivian Deng

Celll/Whastapp:+86 18040529186

Email:[email protected]

Reviews

There are no reviews yet.