Description

Product Description

The nozzle separator is a high-speed, high-precision, closed and efficient separation equipment, mainly used in the solid-liquid two-phase separation and concentration of fermentation broth, chemical and pharmaceutical industries. All parts in contact with materials are made of high-grade stainless steel materials (or specific acid-resistant materials), which can effectively reduce the corrosion of the separated materials and the surfaces of the parts in contact, and meet the food hygiene requirements. The machine adopts the upper feeding form, which has lower requirements for the inlet pressure of the material.

working principle:

The separated material enters the drum of the separator. Under the action of a strong centrifugal force field, the material enters the separation interval of a group of disc bundles from the big end of the disc, and the solid with a larger specific gravity moves along the disc wall to the big end It moves and accumulates in the sediment area and is continuously discharged from the machine by the nozzle. The liquid with a smaller specific gravity moves along the disc wall to the small end of the disc, converges to the centripetal pump at the top of the drum, and is output from the centripetal pump to the next process. The maximum output pressure can reach 0.30Mpa.

Main Specification

| Model | Capacity (L/H) | Inlet pressure | Outlet pressure | Motor power( Kw) | Weight (kg) | Dimension |

| SYN360 | 2000-5000 | 0.05 | 0.1-0.35 | 7.5 | 1200 | 1500*1150*1500 |

| SYN470 | 5000-10000 | 0.05 | 0.1-0.4 | 15 | 1600 | 1800*1200*1800 |

| SYN550 | 10000-20000 | 0.05 | 0.1-04 | 22 | 2300 | 1850*1550*2050 |

| SYN616 | 25000-35000 | 0.1 | 0.3 | 37 | 3300 | 2050*1700*2300 |

* Solid-liquid separation

* Liquid-liquid separation

* Liquid-liquid-solid separation

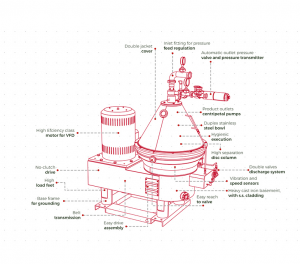

Structure

Application

Hot sale in the Separation of vegetable oil, biodiesel, glycerin, catalyst, crude oil ,soap, methanol methyl washing, extraction of fatty acids, glycerol desalination,starch, diary, animal oil, beer,beverage, biological, pharmaceutical, vegetable extraction, chemical, wast oil, mineral oil,marine…etc.

Packing,Storage,Handling and Transportation

Certificate

FAQ

Product Warranty:

The guarantee period is 12 months from the date of putting the equipment into operation, but not more than 15 months from the date of delivery.

Free service within warranty:

During a warranty period of exploitation the Seller undertakes to execute warranty service of the equipment, troubleshooting and replacement of out of service spares, except for breakings, bound with incorrect exploitation of the equipment by the Buyer.

Set-up and adjusting of the equipment

After receiving the delivered Goods, the Buyer is obliged to prepare, obtained equipment and applicable lodgment for its installation. Then in written form to inform the Seller on readiness of the equipment for chief- equipment installation, start-up and adjusting.

If necessary,The Seller should send enough technical specialists to help execute the chief – equipment installation, start-up and adjusting equipment on the sight of the Buyer.

Export Packing

The Goods are to be shipped in export packing suitable for the type of goods to be delivered. Packing is to protect the Goods against any damage or corrosion when the Goods are transported by sea or by railway and to provide for possible transshipment of the goods on the way to the place of destination and for a long storage of the goods.

Contact

Vivian Deng

Celll/Whastapp:+86 18040529186

Email:[email protected]

Reviews

There are no reviews yet.