Description

Product Description

The decanter centrifuge can clarify, dehydrate or classify the suspension containing solid particles in the range of 0.002-3mm. According to the structural characteristics, the products are divided into three types and series: LWB parallel flow, LW counter flow, and LWS three-phase hierarchical, which can be adapted to the separation of different materials under different working conditions.

The decanter centrifuge is a device that uses the principle of centrifugal sedimentation to separate the suspension. Its working principle is that when the suspension to be separated enters the bowl of the centrifuge, the solid particles with a higher density than the liquid phase then quickly settle to the inner wall of the bowl under the action of the centrifugal force of the bowl, and the screw conveyor inside the centrifuge The solid phase deposited on the inner wall of the drum is pushed to the drying zone at the small end of the drum for further dehydration, and then discharged through the slag outlet, and the separated clear liquid flows out of the overflow weir at the large end of the drum. This decanter centrifuge can continuously feed, separate, wash and discharge materials at full speed. It has the characteristics of compact structure, continuous operation, stable operation, strong adaptability, large production capacity and convenient maintenance. It is suitable for separating suspensions containing solids with a particle size greater than 0.005mm and a concentration range of 2-40%. It is widely used in chemical, light industry, pharmaceutical, food, environmental protection and other industries.

Main Specification

| Model | Capacity (L/H) | Inlet pressure | Outlet pressure | Motor power( Kw) | Weight (kg) | Dimension |

| SYN360 | 2000-5000 | 0.05 | 0.1-0.35 | 7.5 | 1200 | 1500*1150*1500 |

| SYN470 | 5000-10000 | 0.05 | 0.1-0.4 | 15 | 1600 | 1800*1200*1800 |

| SYN550 | 10000-20000 | 0.05 | 0.1-04 | 22 | 2300 | 1850*1550*2050 |

| SYN616 | 25000-35000 | 0.1 | 0.3 | 37 | 3300 | 2050*1700*2300 |

* Solid-liquid separation

* Liquid-liquid separation

* Liquid-liquid-solid separation

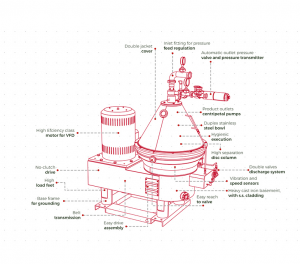

Structure

Application

Mainly used for solid-liquid separation of raw material intermediates and finished products in the industrial fields of food, pharmaceutical, chemical, national defense and other industries. Such as starch, microorganism B, VC sodium, calcium phosphate, baking soda, heavy alkali, polyacrylonitrile and other similar materials separation.

Packing,Storage,Handling and Transportation

Certificate

FAQ

Product Warranty:

The guarantee period is 12 months from the date of putting the equipment into operation, but not more than 15 months from the date of delivery.

Free service within warranty:

During a warranty period of exploitation the Seller undertakes to execute warranty service of the equipment, troubleshooting and replacement of out of service spares, except for breakings, bound with incorrect exploitation of the equipment by the Buyer.

Set-up and adjusting of the equipment

After receiving the delivered Goods, the Buyer is obliged to prepare, obtained equipment and applicable lodgment for its installation. Then in written form to inform the Seller on readiness of the equipment for chief- equipment installation, start-up and adjusting.

If necessary,The Seller should send enough technical specialists to help execute the chief – equipment installation, start-up and adjusting equipment on the sight of the Buyer.

Export Packing

The Goods are to be shipped in export packing suitable for the type of goods to be delivered. Packing is to protect the Goods against any damage or corrosion when the Goods are transported by sea or by railway and to provide for possible transshipment of the goods on the way to the place of destination and for a long storage of the goods.

Contact

Vivian Deng

Celll/Whastapp:+86 18040529186

Email:[email protected]

Reviews

There are no reviews yet.