Description

Product Description

Also known as milk fat separator. A cream separator with a rotating drum was invented in the 1880s, and China began production in the 1950s.

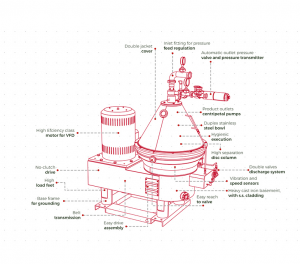

This machine uses centrifugal force to separate the milk fat from the milk, and the degreasing rate is about 99%. There are two commonly used hand-cranked and electric (some models can be used for both hand-cranked and electric). The main working part is a separating bowl (see picture), which is composed of a set of separating pieces, each of which has several 0.4-0.45 mm protrusions on the disc surface, and the separating pieces maintain a uniform distance between them. During operation, the separation bowl rotates at a speed of 6000-12000 rpm, and milk enters from the central pipe. Under the action of centrifugal force, the skim milk is thrown around the separation bowl, moves upward along the inner wall of the bowl cover, and is discharged from the skim milk discharge hole. Milk fat or cream gradually rises along the surface of the separator to the outer wall of the central pipe and is discharged from the milk fat discharge hole. The milk fat discharge hole is provided with an adjusting screw to adjust the fat content of the cream. Due to the high speed, the separating bowl must be accurately balanced, and elastic support is required in the middle of the vertical shaft. On the handle of the hand-cranked cream separator, a speed indicating bell is generally installed. When the speed is lower than the specified value, the bell will ring once every week. When the speed reaches the specified value, the bell will stop, indicating that the specified speed has been reached, preventing the machine Speeding. The productivity of hand crank and electric dual-purpose cream separator is generally 100 to 200 liters/hour, and the power of the equipped motor is generally 180 to 250 watts.

Main Specification

| Model | Capacity (L/H) | Inlet pressure | Outlet pressure | Motor power( Kw) | Weight (kg) | Dimension |

| SYN360 | 2000-5000 | 0.05 | 0.1-0.35 | 7.5 | 1200 | 1500*1150*1500 |

| SYN470 | 5000-10000 | 0.05 | 0.1-0.4 | 15 | 1600 | 1800*1200*1800 |

| SYN550 | 10000-20000 | 0.05 | 0.1-04 | 22 | 2300 | 1850*1550*2050 |

| SYN616 | 25000-35000 | 0.1 | 0.3 | 37 | 3300 | 2050*1700*2300 |

* Solid-liquid separation

* Liquid-liquid separation

* Liquid-liquid-solid separation

Structure

Application

Dairy separator: used for milk skimming or milk clarification (removal of solid impurities). The small separator is driven by hand and is used for manual slagging, which is suitable for farmers and herdsmen in pastoral areas; the large separator is used for industrial production and is driven by electricity. The slagging method is manual slagging or ring valve slagging.

Mineral oil separator: It is used to remove water and mechanical impurities from mineral oil such as fuel oil, diesel oil, lubricating oil and transformer oil, and can also separate similar emulsions.

Vegetable oil separator: used for the processing and refining of vegetable oil.

Animal oil separator: used for refining animal fats in meat processing, or used for concentration and separation of fish oil in aquatic processing.

Yeast separator: used to concentrate yeast and discharge slag from nozzles.

Packing,Storage,Handling and Transportation

Certificate

FAQ

Product Warranty:

The guarantee period is 12 months from the date of putting the equipment into operation, but not more than 15 months from the date of delivery.

Free service within warranty:

During a warranty period of exploitation the Seller undertakes to execute warranty service of the equipment, troubleshooting and replacement of out of service spares, except for breakings, bound with incorrect exploitation of the equipment by the Buyer.

Set-up and adjusting of the equipment

After receiving the delivered Goods, the Buyer is obliged to prepare, obtained equipment and applicable lodgment for its installation. Then in written form to inform the Seller on readiness of the equipment for chief- equipment installation, start-up and adjusting.

If necessary,The Seller should send enough technical specialists to help execute the chief – equipment installation, start-up and adjusting equipment on the sight of the Buyer.

Export Packing

The Goods are to be shipped in export packing suitable for the type of goods to be delivered. Packing is to protect the Goods against any damage or corrosion when the Goods are transported by sea or by railway and to provide for possible transshipment of the goods on the way to the place of destination and for a long storage of the goods.

Contact

Vivian Deng

Celll/Whastapp:+86 18040529186

Email:[email protected]

Reviews

There are no reviews yet.